Tesla batteries are made through a complex manufacturing process that involves assembling individual battery cells into modules and then combining these modules to form a complete battery pack. The batteries are designed and produced using advanced technologies and materials to ensure high performance and reliability in Tesla vehicles.

The Rise Of Tesla Batteries

Tesla has revolutionized the electric vehicle (EV) industry by leveraging its innovative battery technology. These cutting-edge batteries have significantly impacted EVs’ performance, range, and success. Let’s delve into the details of Tesla’s battery production process and explore how it has redefined the world of electric vehicles.

Innovative Battery Technology

Tesla’s innovative battery technology is at the heart of its success. The company’s batteries are based on lithium-ion cells, commonly used in portable electronics like smartphones and laptops. However, Tesla has advanced this technology by developing more extensive and powerful battery packs designed for EV applications.

The key to Tesla’s battery innovation lies in its proprietary manufacturing process. The company carefully controls the composition and structure of its battery cells, optimizing them for maximum energy density, longevity, and safety. Tesla’s batteries incorporate advanced cooling systems to prevent overheating and ensure efficient energy transfer.

This groundbreaking battery technology allows Tesla’s vehicles to achieve impressive performance metrics while maintaining long-lasting battery life. The combination of high energy density and efficient cooling systems translates into enhanced range, faster acceleration, and improved overall driving experiences for Tesla owners.

Impact On Electric Vehicles

The impact of Tesla’s batteries on the EV industry cannot be overstated. These high-performance cells have significantly improved the viability and desirability of electric vehicles, addressing two of the most common concerns: range anxiety and lackluster performance.

One of the most notable benefits of Tesla’s battery technology is its effect on range. Tesla vehicles can travel longer distances on a single charge by optimizing energy density. This has alleviated many potential EV buyers’ anxiety about running out of battery power on longer journeys.

With Tesla, drivers can confidently embark on road trips and commutes without worrying about finding charging stations at every turn.

Tesla’s batteries have also had a profound impact on the performance of electric vehicles. The instant torque provided by these advanced batteries allows Tesla cars to accelerate quickly, rivaling or surpassing the speed of traditional gasoline-powered vehicles.

This has shattered the stereotype of electric cars as slow and unimpressive upon launch, attracting performance-oriented consumers who desire both eco-friendly aspects and thrilling driving experiences.

Moreover, Tesla’s battery technology has spurred innovation across the EV market. As more automakers strive to compete with Tesla’s success, they have invested heavily in developing their advanced batteries.

This has resulted in a broader range of EV options for consumers, encouraging the mainstream adoption of electric vehicles globally.

Components Of Tesla Batteries

Tesla is renowned for its cutting-edge electric vehicles and their advanced battery technology. The components of Tesla batteries are carefully engineered to deliver high performance and efficiency. Let’s explore the key components: battery cells and battery packs.

Battery Cells

Tesla’s battery cells are the building blocks of their battery packs. These cells are cylindrical and are commonly known as 2170 cells. ‘2170’ refers to their size, with a diameter of 21mm and a length of 70mm. These cells are more significant than those used in previous models, allowing Tesla to pack more energy into each battery pack.

Each battery cell has multiple layers, including a cathode, an anode, a separator, and an electrolyte. The cathode and anode are responsible for storing and releasing electrical energy, while the separator ensures they don’t come into direct contact to prevent short circuits.

One of the key materials used in Tesla battery cells is lithium-ion. Lithium ions move from the cathode to the anode during charging and back again during discharge, generating electrical energy. Tesla has also developed their proprietary battery chemistry, utilizing a combination of materials like nickel, cobalt, and aluminum to enhance the performance and longevity of the cells.

Battery Packs

The battery cells are assembled into battery packs, which power Tesla vehicles. These packs comprise thousands of individual battery cells connected in series and parallel configurations.

One of the notable features of Tesla battery packs is their thermal management system. This system actively monitors and regulates the temperature of the cells, ensuring they operate within the optimal range. This enhances the performance and lifespan of the battery pack and improves safety.

Additionally, the battery packs include a Battery Management System (BMS) that controls the charging and discharging of the cells. The BMS also provides crucial information about the state of charge, capacity, and overall health of the battery pack to the vehicle’s onboard computer system.

Tesla vehicles are designed with multiple battery packs strategically placed throughout the chassis to optimize weight distribution and stability. This setup allows for efficient energy utilization and extends the vehicle’s driving range.

Manufacturing Process

Tesla’s battery manufacturing process is an intricate and highly optimized operation crucial for the functionality and performance of its electric vehicles. Let’s delve into the different stages of Tesla’s battery production and assembly process to understand the complexity and precision of creating these cutting-edge power sources.

Cell Production

The first step in the manufacturing process of Tesla batteries is cell production. This stage involves the creation of the individual cells that collectively form the battery pack. The cell production starts with assembling electrode materials, including the cathode, anode, and electrolyte.

These components are combined to form the cell and then undergo a series of quality checks and testing to ensure they meet Tesla’s stringent standards for performance and safety.

Pack Assembly

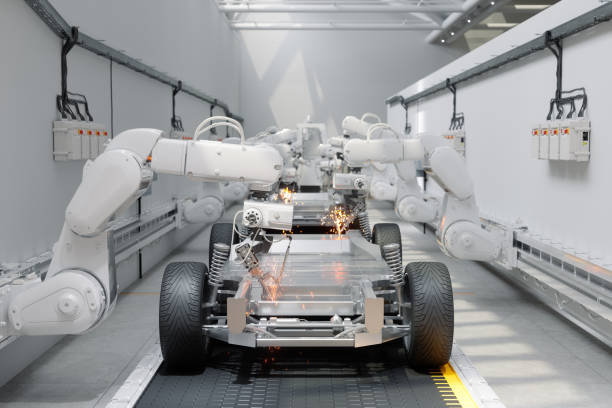

Once the cells are produced, the next stage in the manufacturing process is pack assembly. This involves integrating the individual cells into a cohesive battery pack, incorporating control electronics, thermal management systems, and the final enclosure.

The pack assembly process is highly automated and precise, with each component inspected and tested to guarantee optimal functionality and longevity. Tesla’s advanced manufacturing techniques and quality control measures ensure that every battery pack meets the company’s high energy density, reliability, and safety standards.

Sustainability Efforts

Tesla batteries are manufactured using sustainable practices, prioritizing using renewable energy sources and minimizing environmental impact. Materials are responsibly sourced and recycled, contributing to a lower carbon footprint. The company’s commitment to sustainability is evident in every step of the battery production process.

As a company committed to reducing its environmental impact, Tesla goes the extra mile to ensure sustainability throughout its battery production process. From recycling initiatives to reducing carbon emissions, Tesla prioritizes eco-friendly practices every step of the way.

Recycling Initiatives

Tesla recognizes the importance of responsible waste management and has implemented robust recycling initiatives. They have partnered with recycling companies to recycle used batteries and other components, preventing them from ending up in landfills.

Through these recycling efforts, Tesla recovers valuable materials from old batteries and reintroduces them into manufacturing. This closed-loop system reduces the demand for new raw materials and minimizes environmental pollution.

Reducing Environmental Impact

Tesla constantly explores innovative ways to reduce its environmental impact. One significant aspect is their dedication to minimizing carbon emissions during battery production.

By investing in renewable energy sources such as solar panels and wind turbines, Tesla powers its factories using clean energy. The reliance on renewable energy ensures battery manufacturing has a significantly smaller carbon footprint than traditional production methods.

In addition, Tesla is dedicated to optimizing its supply chain to reduce transport-related emissions. By strategically locating its Gigafactories near raw material sources, Tesla can minimize the distance traveled by materials and reduce transportation-related carbon emissions.

Future Developments

The future developments in Tesla’s battery technology are poised to revolutionize how we use and store energy. The possibilities are endless with advancements in battery technology and the integration of renewable energy systems. Let’s explore these exciting developments in more detail:

Advancements In Battery Technology

One of the critical areas of future development lies in improving battery technology. Tesla is continually working on enhancing the capacity and performance of their batteries, allowing for longer ranges and faster charging times.

These advancements are made possible through innovative materials and manufacturing techniques. Tesla’s batteries utilize lithium-ion technology, which offers high energy density, longer lifespan, and improved efficiency.

The company also invests in research and development to explore alternative battery chemistries, such as solid-state batteries. These batteries have the potential to increase energy storage capacity further and improve overall battery performance.

Integration In Renewable Energy Systems

Tesla’s batteries are not only designed for electric vehicles but also to support renewable energy systems. With the increasing adoption of solar and wind power, energy storage is crucial to harnessing the full potential of these renewable sources.

By integrating Tesla’s batteries with renewable energy systems, excess energy generated during peak production can be stored and utilized during periods of high demand or when renewable sources are unavailable. This enables a more stable and reliable energy supply.

Furthermore, these integrated systems can help reduce reliance on fossil fuels and contribute to a greener and more sustainable future. They offer a viable solution to address the intermittency issues associated with renewable energy sources and pave the way for a decentralized and resilient energy grid.

Overall, future developments in Tesla’s battery technology hold immense promise. Through advancements in battery technology and integration in renewable energy systems, we can expect more efficient, longer-lasting batteries and a more sustainable energy landscape.

Are Tesla batteries bad for the environment?

Like any technology, the environmental impact of Tesla batteries involves both positive and negative aspects. Here are some key points to consider:

Positive Aspects:

- Reduced Emissions: Electric vehicles powered by Tesla batteries contribute to lower greenhouse gas emissions compared to traditional internal combustion engine vehicles, especially when charged using renewable energy sources.

- Energy Efficiency: Electric vehicles are generally more energy-efficient than their gasoline counterparts, as electric motors are more efficient in converting stored energy into motion.

- Innovation: Tesla has been a leader in advancing battery technology, contributing to developing more efficient and longer-lasting batteries. This can lead to overall improvements in renewable energy storage and utilization.

Negative Aspects:

- Mining Impact: The production of lithium-ion batteries, commonly used in electric vehicles, including Teslas, involves the extraction of metals like lithium, cobalt, and nickel. The mining process can have negative environmental and social impacts, including habitat destruction, water pollution, and issues related to workers’ rights in some cases.

- Battery Disposal: While electric vehicle batteries have a long lifespan, they eventually reach the end of their life cycle. Proper disposal and recycling of these batteries are crucial to prevent environmental harm. Currently, there are challenges in recycling and disposing of lithium-ion batteries.

Efforts to Address Issues: Tesla and other companies are actively working on improving the environmental sustainability of their products:

- Recycling Initiatives: Tesla has expressed its commitment to recycling and has implemented programs to recover and reuse materials from its batteries.

- Reducing Dependence on Critical Materials: Companies are exploring alternative battery chemistries that use fewer or no critical materials like cobalt, which could reduce the environmental impact of battery production.

- Lifecycle Analysis: Evaluating the entire lifecycle of a product, from raw material extraction to manufacturing, use, and disposal, helps identify areas for improvement in terms of environmental impact.

In summary, while Tesla batteries contribute to reducing emissions and advancing clean energy, environmental concerns are associated with their production and disposal. Ongoing efforts within the industry aim to address these challenges and make electric vehicles more environmentally sustainable.

How are Tesla batteries disposed of

Frequently Asked Questions On How Are Tesla Batteries Made

How Are Tesla Batteries Made?

Tesla batteries are made using advanced manufacturing processes and technologies. They start with raw materials like lithium, which are extracted and processed into battery-grade form. These materials are combined to create the different battery layers, including the anode, cathode, and electrolyte.

The battery cells are assembled into modules and battery packs used in Tesla vehicles and energy storage systems.

What Materials Are Used In Tesla Batteries?

Tesla batteries are primarily composed of lithium, used in the anode and cathode of the battery cells. Other materials used include nickel, cobalt, and aluminum. These materials are chosen for their specific properties, enabling high energy density, long cycle life, and fast charging capabilities.

Tesla is also working towards reducing its reliance on cobalt in its batteries to make them more sustainable and cost-effective.

How Long Do Tesla Batteries Last?

Tesla batteries are designed to last for a long time. The current warranty on Tesla Model S and Model X battery packs is 8 years or 150,000 miles, whichever comes first. For Model 3 and Model Y, the battery warranty varies depending on the configuration, ranging from 8 years or 120,000 miles to 8 years or 300,000 miles.

With proper maintenance and usage, Tesla batteries can last even longer, providing reliable performance for many years.

What are Tesla batteries made of?

Tesla batteries primarily use lithium-ion technology. The main components include lithium-cobalt oxide or lithium-nickel-cobalt-aluminum oxide cathodes, graphite anodes, and an electrolyte solution containing lithium salts. Additionally, there are other materials such as separators, current collectors, and a protective casing.

What are the raw materials for Tesla battery?

The raw materials for Tesla batteries include lithium, cobalt, nickel, aluminum, graphite, and other materials used to produce cathodes, anodes, electrolytes, and other components.

Where does Tesla get its lithium?

Tesla sources lithium from various suppliers globally. The specific suppliers and locations may vary as Tesla seeks to secure a diverse and sustainable battery supply chain.

How many cells are in a Tesla battery?

The number of cells in a Tesla battery varies across models. A Tesla Model S battery pack contains around 8,000 cells, while the Model 3 has approximately 4,000 cells. Keep in mind that newer models or updates may have different configurations.

How heavy is a Tesla battery?

The weight of a Tesla battery depends on the model and capacity. A Tesla Model S battery pack weighs around 1,200 pounds (about 544 kilograms), and a Model 3 battery pack weighs roughly 1,000 pounds (about 454 kilograms). Weight may vary with newer models or changes in battery technology.

Does Tesla build its own battery?

Yes, Tesla manufactures its batteries. Tesla has its Gigafactories, where it produces battery cells and packs for its electric vehicles and energy products.

Conclusion

The process of making Tesla batteries is an innovative and complex one. From souPrecisiontainability is evident at every step. The result, from sourcing materials to manufacturing, is a high-performance battery pack at the forefront of green technology.

With continuous research and development, Tesla is shaping the future of electric mobility.

I am Nishadujjaman.I have two years of experience all types of battery like tesla battery,car battery etc. So I work on solving these issues and give various tips on these issues.